Saxony’s State Secretary Kralinski visits demonstration plant of AMBARtec

Free State of Saxony supports Saxony's hydrogen economy.

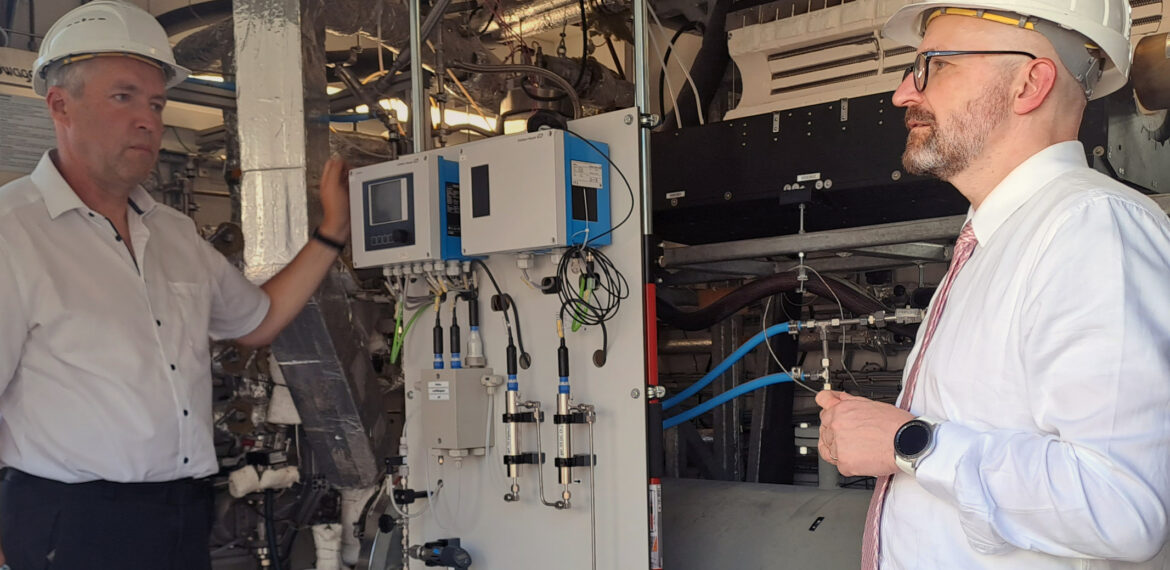

Dresden/Freiberg, 30 August 2024. Thomas Kralinski, Head of Office and State Secretary of the State Ministry of Economic Affairs, Labour and Transport of the Free State of Saxony, visited AMBARtec AG's demonstration plant with a storage system for efficient hydrogen transport in Freiberg on 29 August to see for himself the numerous advantages of AMBARtec's highly innovative technology. The special feature is that the hydrogen, or rather its energy, is stored and transported using iron oxide nuggets - similar to small stones. One of the major advantages of this technology, which has been developed exclusively by AMBARtec, is not only its high efficiency and safety, but also its immediate availability – without the need for lengthy adaptations to the infrastructure and complex approval procedures.To get the Saxon hydrogen economy off the ground

The containerised hydrogen storage systems developed by AMBARtec can be deployed quickly. They require no structural changes to the infrastructure and can be transported and handled using standard logistics such as trucks, trains or cranes. AMBARtec will therefore enable industrial companies to supply themselves with hydrogen at comparatively low cost from as early as 2025. This will give them a significant strategic and time advantage, allowing them to prepare for the transition to the hydrogen network. The hydrogen economy in Saxony is picking up speed! 'We have a large number of companies in Saxony that want to use hydrogen in the future and want to gain initial experience now,' said State Secretary Kralinski. 'It is therefore all the more important that storage solutions are already available today to enable companies to adapt to the new energy source.'

Significant reduction in authorisation effort

The storage material consists of iron oxide nuggets that resemble small stones. During storage, the added hydrogen reduces the iron oxide to iron. For discharging, steam is added which reacts with the iron. This produces iron oxide and hydrogen again. As no hydrogen can escape from the storage systems, even when loaded, and they are therefore not dangerous goods, the approval procedures are greatly simplified. No permits are required under the Industrial Safety Ordinance (Betriebssicherheitsverordnung) or the Hazardous Incident Ordinance (Störfallverordnung). 'We feed the water vapour produced during loading back into the electrolysis process,' explains Technical Director Uwe Pahl. 'Thanks to this closed water cycle and the up to 90 per cent reduction in water consumption during hydrogen production, our unique technology eliminates all requirements for electrolysers arising from the Water Resources Act (Wasserhaushaltsgesetz).'

Successful support of the hydrogen industry by the Free State

In addition to numerous economic policy measures, Saxony also provides its companies with considerable support in the development and implementation of suitable hydrogen technologies. 'For example, we receive support in the area of STEM employee retention and innovation bonuses,' says Matthias Rudloff, CEO of AMBARtec. 'Without these important subsidies, we would not be able to advance the development of storage systems to the same extent, or at least not as quickly, as we are still a small company. We are pleased that the government will continue to support the domestic hydrogen industry in the future.'

Presscontakt:

Dr. Ines Bilas

AMBARtec AG

Head of Marketing and Communication

Phone: +49 172 234 11 00

Email: ines.bilas@ambartec.de

Website: www.ambartec.de