Nugget vessel for 6000-liter hydrogen storage system certified

AMBARtec and Purem by Eberspächer prepare for series production.

Dresden, Esslingen, December 15, 2025 – The renowned testing institute LRQA Germany has tested and approved the design of the nugget vessel for AMBARtec's 6,000-litre storage system. AMBARtec and Purem by Eberspächer are intensifying their cooperation in preparation for the series production of the H2compact 6000.

The H2compact 6000 is going into series production.

Following successful testing in accordance with the Pressure Equipment Directive 2014/68/EU, the 6,000-litre Nugget vessel storage system has cleared all hurdles and will receive its CE certificate shortly. ‘This marks a significant milestone for series production,’ reports Matthias Rudloff, CEO of AMBARtec. 'We are delighted to have Purem by Eberspächer as an experienced and committed partner, who are now pressing ahead with preparations for series production at its site in Wilsdruff, Saxony. Next year, our customers will be able to purchase the first containers, after which we plan to ramp up production to several hundred containers," he continues.

Start of industrialisation at the Purem by Eberspächer plant in Wilsdruff

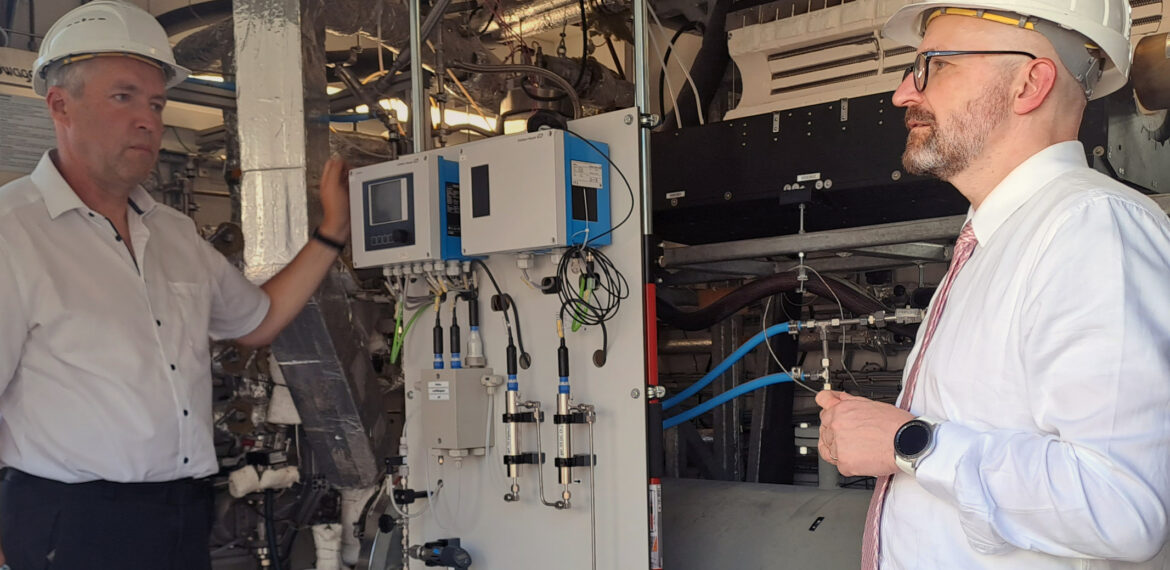

The exhaust and acoustics specialist is preparing for the series production of pressure vessels by developing a modular production concept. Thanks to its existing expertise in industrialisation and many years of experience in steel processing, Purem by Eberspächer is well placed to translate the AMBARtec prototype design into scalable production. To meet the stringent requirements of welding technology, the company is providing its production staff with targeted further training.

A long-term partnership that goes beyond container manufacturing.

Purem by Eberspächer has been involved in designing and developing AMBARtec's containers since the two companies began collaborating in January 2025. For its part, the company, headquartered in Esslingen near Stuttgart, is integrating AMBARtec into its existing business relationships. "By connecting us with strategic partners, including those in the steel industry and other companies in the hydrogen economy, Purem by Eberspächer is opening up new market segments for us," emphasises AMBARtec's Chief Technical Officer, Uwe Pahl. 'This involves both the storage and transport of hydrogen, as well as our offer to supply companies with silver hydrogen.' This is recycled hydrogen, produced as waste gas in various sectors of the economy, which can be captured and reused with AMBARtec storage technology.

800 kg of hydrogen per container.

The H2compact 6000 Plus has a storage capacity of 800 kg of hydrogen or 26 MWh. Installed in conventional 20-foot containers, it can be transported using standard logistics methods, such as lorries, ships, rail and cranes. No adjustments to the infrastructure are necessary, nor are there any lengthy approval procedures under the Federal Immission Control Act (BImSchG) or the Hazardous Incident Ordinance. Extensive operational testing has confirmed the cycle stability of the storage material, making the containers suitable for continuous use.

Pressekontakt:

Dr. Ines Bilas

AMBARtec AG

Head of Marketing and Communication

Phone: +49 172 234 11 00

E-Mail: ines.bilas@ambartec.de

Website: www.ambartec.de